Continuous Inkjet

Videojet® 1710

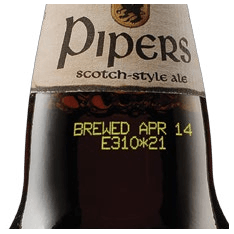

Superior uptime in diverse applications for easily readable codes. The Videojet 1710 is designed for customers requiring high contrast codes on dark or hard to mark substrates.

For applications that require easily readable variable data codes on dark or difficult to mark materials, Videojet has designed the Videojet 1710 small character continuous inkjet printer. The printer uses

high-contrast, pigmented inks to create bright, clean codes on surfaces for which dye-based inks are not effective, such as colored glass, rubber tubing, plastic cabling and dark paperboard. It is capable of printing a variety of fonts in multiple languages, as well as linear bar codes, 2D DataMatrix codes, custom logos and graphics.

Uptime Advantage

- CleanFlow™ technology resists ink build up that can cause

ordinary inkjet printers to shut down - New conical ink reservoir minimizes natural effects of pigment

settling - Long run time between preventive maintenance; core life of up

to 4,000 hours or 12 months, whichever occurs first - Auto cleaning printhead for fast start-ups even after extended

shutdowns

Built-in productivity

- Dynamic Calibration™ adjusts jetting parameters automatically

to ensure high quality print - The unique fluid system assures proper dispersion of pigments

while printing, or when idle for long periods of time - Print from 1 to 5 lines of text at high speeds

Special core engineered for pigmented ink

- Intelligent clustering of pigmented filters and components

with similar life spans for reliability and easy maintenance - New conical ink reservoir minimizes natural effects of

pigment settling - Core eliminates messy filter and pump replacement

Unique fluid capabilitie

- High-contrast, pigmented inks create bright, clean codes on dark

or difficult surfaces - Innovative fluid management system simply and reliably delivers

ink to the products you need coded without significant operator

intervention - Smart Cartridge™ fluid delivery system to virtually eliminate spills

and help ensure the correct fluids are being used

Simple usability

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and

maintenance - Prompted user fields to help reduce coding errors

Printhead extends intervals between cleaning

- High-efficiency nozzle reduces printhead cleaning through

precisely formed and directed ink drops - Manifold circulates fluids to enable clean starts/stops

- Specially filtered air from perforated front face directs ink and

dust away from printhead to reduce build up - Smooth deck for easy cleaning of pigmented ink

Videojet® 1710

if you need more information don’t hesitate to contact us

Videojet® 1710

Continuous Inkjet

Line speed capability

1-5 lines of print, up to 888fpm (271mpm) at 60 dpi (see Print Sample Guide)

Font matrix configuration

Resolution range; 5×5 through 25×34 dot matrix (see Print Sample Guide)

Linear bar codes*

UPC-A/E, EAN-8/13, Code 128 A/B/C, UCC/EAN 128, Code 39, I 2 of 5, GS1

DataMatrix codes*

10×10 through 32×32 and 18×8 through 48×16

Nominal character height

0.080” (2mm) – 0.40” (10mm), font dependent

Throw distance

0.2” (5mm) – 0.6” (15mm), 0.5” (12mm) optimal

Keyboard

Membrane tactile feedback. 72 alpha-numeric and special function keys.

Approximates international PC convention

Display

320×240 bright backlit LCD display, 5.7” (14.5cm)

Custom logo/graphics

Created by user on printer or on PC and imported via USB

Character sets

English, Arabic, Bulgarian, Chinese, East European, Greek, Hebrew, Kanji, Korean, Russian, Scandinavian, Turkish

Languages and interface options

English, Arabic, Bulgarian, Simple Chinese, Traditional Chinese, Czech, Danish, Dutch, Finnish, French, German, Greek, Hebrew, Hungarian, Italian, Japanese, Korean, Norwegian, Polish, Portuguese, Russian, Spanish, Swedish, Thai, Turkish, Vietnamese

Data interface

RS232 serial, Ethernet (optional)

Clarisoft/Clarinet® via RS232 and ethernet

Message management via USB

Message storage

250 messages standard

Environmental protection

IP55 (IP65 option, no plant air required); stainless steel cabinet

Printhead

Positive air standard

Diameter 1.63” (41.3mm), length 10.62” (269.8mm), 60/70 micron nozzle

Printhead umbilical

Length 9.8’ (3m), optional 19.7’ (6m), diameter 0.9” (23mm),

bend radius 3.0” (76mm)

Fluids containers

Ink; 0.63 qt (600ml) and Make-Up; 0.79 qt (750ml) cartridges

Temperature/humidity range

41 ºF to 113 ºF (5 ºC – 45 ºC), 0-90% RH (non-condensing)

With selected inks; actual installation may require additional hardware

based on production environment conditions

Electrical requirements

100-120 / 200-240 VAC at 50/60 Hz, 120 WW

Approximate weight

46 lbs (21kg)

Options

IP65 with 316 stainless steel (no plant air required)

Dry air kit for high humidity (requires plant air)

60 or 70 micron nozzle

Food grade version

90 degree printhead

Wide range of accessories