Continuous Inkjet

Videojet DataFlex® 6330

The Videojet DataFlex® 6330 combines the need for code accuracy with the even higher quality technology, therefore reducing time and packaging waste, to give an overall more productive operation.

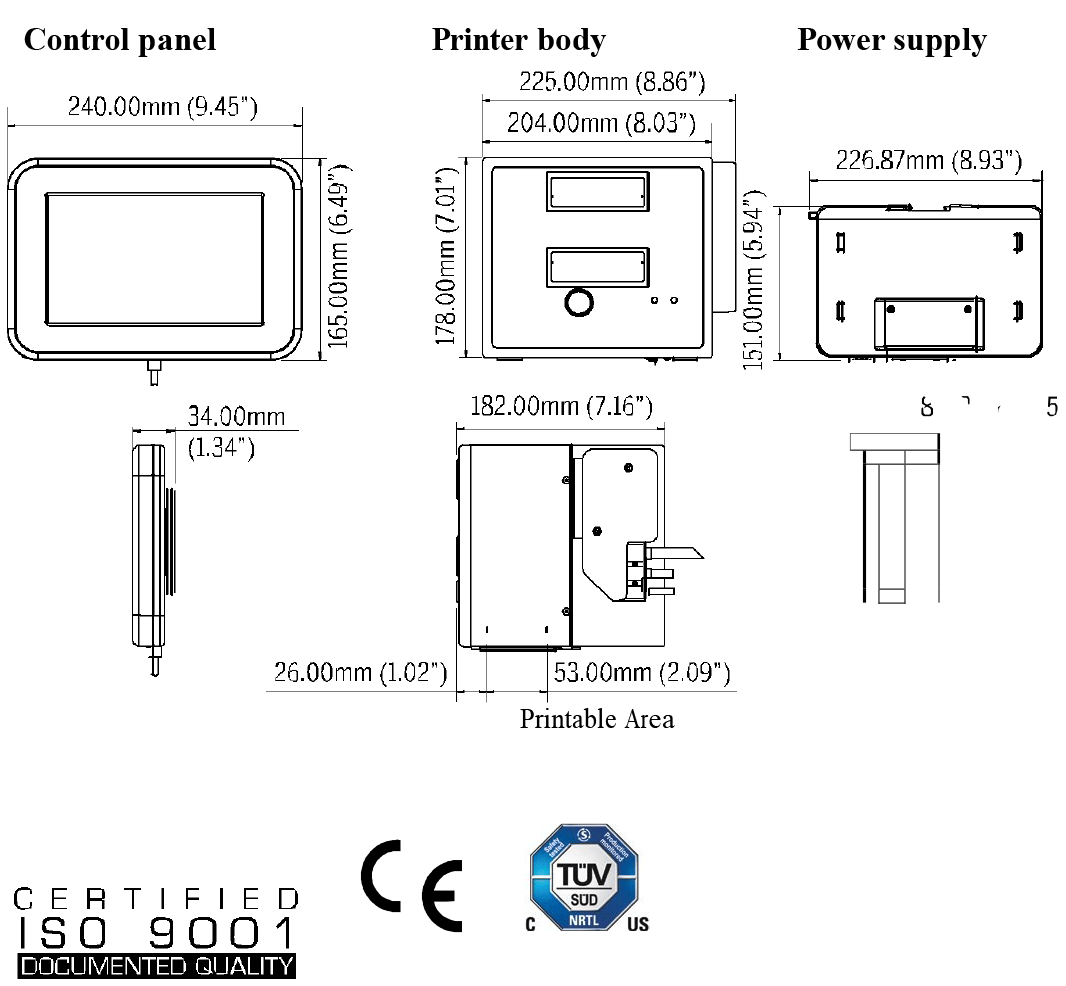

Featuring a 53mm printhead that performs both intermittent printing and continuous printing at a maximum speed of 750mm/second, the 6330 is built with an intelligent design to withstand tough production

line environments, and intelligent maintenance with minimal parts wear and easy to change ribbons. The Videojet DataFlex® 6330 comes standard with Videojet iAssure™ code quality assurance technology,

which automatically detects common print defects, helping to ensure high-quality codes are applied to your packages time after time.* Combined with our CLARiTY™ software, the 6330 reduces the potential for print and coding errors, reducing waste and rework with no extra

manpower or equipment.

Uptime Advantage

- Intelligent Motion™ technology removes the need for compressed air and associated costs and downtime, which helps maximize consistent print quality and printhead life

- Discover code legibility issues that indicate the potential need for printer maintenance

- Industry-leading simple cassette change is designed for fast ribbon replacement to help maximize uptime

Built-in productivity

- Default settings and no factory air gauge help maintain consistent code quality and avoid the risk of operators over-adjusting conventional air and energy settings

- Quick change printhead and minimal wear parts can reduce the time that production is interrupted when replacements are required

Code Quality Assurance

- iAssure™ technology automatically detects common print defects before pallets of product stack up, cause unwanted waste or reworked product and require additional operator time to correct the error*

- CLARiTY™ software helps ensure the right code is consistently printed on the right product

Easy usability

- Bright display with WYSIWYG and function keys for easy operation

- Store up to 100 complex messages for easy recall – store even

more messages using a standard USB memory stick - User levels to separate operation from installation and

maintenance

Videojet DataFlex® 6330

if you need more information don’t hesitate to contact us

Videojet DataFlex® 6330

Continuous Inkjet

Printhead

53mm, 300dpi (12dot/mm)

Print area

Intermittent printing mode: 2.1” (53mm) wide x 3.0” (75mm) long

Continuous printing mode: 2.1” (53mm) wide x 7.9” (200mm) long

Minimum print speed (1)

Intermittent mode: 1.6 in./sec (40mm/sec) full print quality; 0.4 in./sec (10mm/sec) draft

mode print quality

Continuous mode: 1.6 in./sec (40mm/sec) full print quality; 0.04 in./sec (1mm/sec)

draft mode print quality

Maximum print speed (1)

29.5 in./sec (750mm/sec)

Maximum throughput (1)

Up to 250 prints per minute

iAssureTM code quality assurance detector (2)

Detectable Defects

Damaged print platen/roller

Dirty printhead

Damaged printhead

Ribbon wrinkles

Uneven print surface

Overprints

Misaligned printhead

Printing capabilities

Full downloadable font support using TrueType® fonts (including multiple languages and Unicode support); fixed, variable and merged text fields; flexible date/time formats; flexible shift code formats; auto best before date calculations and concession management; calendar rules; auto incrementing decrementing text, counters and bar codes; multiple graphic formats supported (up to maximum print area); link fields to databases; scalable text and text blocks

Bar codes

EAN 8, EAN 13, UPC-A, UPC-E, Code 39, EAN 128, Code 128, ITF, RSS (including 2D

composite codes), DataMatrix, QR; others available upon request

Operator interface

TFT SVGA 800×480 full-color LCD and touch screen, WYSIWYG print preview, full on-board diagnostics, 3 levels of password protection, extensive language support

Ribbon range

Full assortment of wax/resin and resin ribbons

Maximum ribbon length

Lengths up to 1,200 meters available, dependent on ribbon composition and color

Ribbon widths

0.8” (20mm) min, 2.2” (55mm) max

Nominal gap between successive prints

0.02” (0.5mm)

Ribbon saving features

Radial, interleaved, intermittent stripes

(1) Application dependent

(2) iAssureTM technology complements existing quality control processes. It is not designed to detect all printing errors, does not read bar codes and is not currently supported for use with ribbon saving print modes.

Image design software

CLARiSOFT®

Network management software

CLARiNET™

Remote coder configuration software

CLARiTYTM Configuration Manager

“Off-line” set up and parameter storage available as standard

Make-up fluid consumption

As low as 2.4ml per hour

Fluids containers

Ink Smart Cartridge™ 0.793 qt. (750ml)

Make-Up Smart Cartridge 0.793 qt. (750ml)

Temperature/humidity range

32°F to 122°F (0°C to 50°C)

0% to 90% RH non-condensing

With selected inks; actual installation may require additional hardware based on production

environment conditions

Electrical requirements

Nominal supply power 100-120 / 200-240 VAC at 50/60 Hz., 120 W

Approximate weight

Unpacked and dry: 39.68lbs. (18kg)

Options

Positive air pump

Dry air kit for high humidity (requires plant air)

Product detect, relay, RS 485 expansion board

RS232, encoder, beacon expansion board

9.8-foot (3 m) umbilical

60 or 70 micron nozzle

Food grade version

90 degree printhead

Wide range of accessories